Special intelligent boiler drum level gauge

Products overview:

ZW - BGL seriesSpecial intelligent boiler drum level gaugeUsing tomography technology, through the analysis of the sensor scans and special liquid level meter in the dielectric constant and the temperature of the liquid phase and gas phase, the dynamic compensation.After comparison operation system software, the output is proportional to the boiler liquid level standard of 4 ~ 20 ma current signal and four groups of SPST solid state relay switch signal.The liquid level meter in the process of running a bit is not affected by dielectric constant change, boiler temperature and steam interference is no effect on the liquid level meter, the measurement accuracy is more than one over one thousand, long-term stability is very good, almost no drift, comprehensive performance is unparalleled, other measuring methods is a full process, high precision, high reliability of boiler liquid level gauge.

For boiler drum level meter in the process of running a bit is not affected by dielectric constant change, the boiler temperature, steam jamming is no effect on the liquid level meter, such as its measurement precision reached more than one over one thousand, long-term stability is very good, almost no drift, comprehensive performance is incomparable to other measurements, it is a full process, high precision, high reliability of boiler liquid level gauge.

The importance of the boiler steam drum water level measurement is well known, however the boiler steam drum water level for a long time continuous measurement technology adopted balance container type (differential pressure type) there are many failed to improve the method of measurement of defects, mainly embodied in the following aspects:

1, can't implement all condition survey, there are "false water level" measurement, rev, stop, emptying in boiler, a platoon, accident to establish stable and unstable operating condition differential pressure condition for a long time, for a long time or simply can't establish normal differential pressure, need human intervention.

2, under the condition of the stability conditions, due to the structure limit, can't completely solve system caused by water side off temperature measurement error compensation.Deficiency, filled with water in boiler accidents such as working conditions, the system measurement error is too large may lead to serious consequences

More than 3, complicated structure, static sealing points, the construction scale and winter insulation problems.

4, measuring time-delay longer, not immediate reaction boiler water level change, poor quality of measurement signal conditioning.

5, due to the cooling barrel exothermic, the use of high cost.

These defects are due to differential pressure type measuring principle and the system sampling caused by unreasonable structure, cannot be improved.Under abnormal conditions for the safe operation of the boiler caused great hidden trouble.

To thoroughly solve the problems existing in the steam drum water level measurement, our company according to working condition of boiler steam drum water level measurement and control professional design produces ZW - BGL series special boiler drum level gauge.

Second, the working principle:

ZW - BGL series intelligent special boiler drum level gauge is based on the principle of capacitance measuring liquid level meter, the tomography technology, through the analysis of the sensor scans and special liquid level meter in the dielectric constant and the temperature of the liquid phase and gas phase, the dynamic compensation.After comparison operation system software, the output is proportional to the boiler liquid level standard of 4 ~ 20 ma current signal and four groups of SPST solid state relay switch signal.Can also be output supply using RS485 digital signals.Liquid level meter in the running process real-time dynamic compensation, to reduce factors such as temperature, pressure change to small zui, long-term stability is good, is a full process, cost-effective liquid level gauge.

Applications:

ZW - BGL series intelligent special boiler drum level gauge adopts special structure, resistance to high temperature and high pressure, the liquid level transmitter use and to explore the relationship between the changes of capacitance measurement, using a special model system software will detect the capacitance change after all kinds of compensation calculated output is proportional to the level of the standard 4-20 madc signal.Can be widely used in all kinds of industrial steam drum, plus, low and high, conversion furnace such as liquid level measurement and control of pressure vessel.

Four, the main features:

1, strong practicability, simple operation

Analog circuit of zero and range each other, need many times to calibration;Intelligent circuit set with buttons, a key calibration, the operation is very simple and accurate.

2, according to stability

Analog circuits can be difficult to achieve the larger damping and sampling time, in the process of production, little older gas or liquid level micro, will lead to the instability of monitoring instrument display, monitor the loss of visual exhaustion;Intelligent liquid level meter adopts digital technology, software filtering is not affected by swing in the air and liquid level, which can fast track transient changes, and can show the average level effect, stable and accurate.

3, large scope of work

Analog circuit due to the limitation of hardware, high working voltage, most of the working voltage above 14 v, when with current safety barrier is smaller, slightly higher level to cause a decline in voltage, cause display abnormal, thus misleading operator, even caused the accident;Intelligent liquid level meter in 9-36 v voltage all can work normally, meet any type of safety barrier.

4, strong anti-jamming capability

Most of the analog circuit direct access to the microcomputer system, will be affected by other device signal, causing instability, and even can't work;Intelligent liquid level instrument with software and hardware anti-interference and error correction technology, made in the explosion-proof, without isolation, direct access, both to reduce the complexity of the circuit, and reduces the cost.

5, powerful

Liquid crystal display, can display the current value, percentage, or the scene temperature, etc., equipped with all kinds of communication interface and debugging interface.

6, high precision and strong general performance

Intelligent temperature compensation and the linear correction, automatic linear range tracking, and is suitable for requiring higher precision and stability.

Five, the performance parameters:

Working voltage: z: 36 v.Small z: 9 v.

Current loop: two wire 4.00 mA ~ 20.00 mA (+ / - 0.2%);

Explosion-proof level: ExiaIICT6 ExiaIICT1 (to 40 ℃ ~ 70 ℃) to 5 (- 40 ℃ ~ 85 ℃);

Explosion-proof parameters: Ui = 30 v, 2 = 100 ma, Pi = 0.75 m3 WCi = 100, Li = 10 uh solid state relay (each group) Ui = 30 v, 2 = 100 ma, Pi = 0.75 WCi = 150 pf, Li = 10 uh;

Measuring range: 0 ~ 2200 mm;

Measurement cycle: 0.5 seconds;

Resolution: 0.01 mm;

Temperature drift: + / - 0.05 mmMax (- 40 ℃ ~ 85 ℃);

Job stress: 40 mpa;

Linear deviation: + (1 + 0.05% FS) mm;

Medium temperature: 450 ℃;

Ambient temperature: - 40 ℃ ~ 85 ℃ (ExiaIICT1 - T5);

Storage temperature: 55 ℃ ~ 100 ℃;

Protection grade: IP67.

Solid state relay:

Configuration: four groups SPST (NO) solid state relay;

Load voltage: 220 vac / 30 VDC / 300 VDC (not explosion-proof) AC (explosion-proof place);

Load current: 500 ma;

, alarm mode: "alarm" optional five independent optional alarm mode;

Delay: 1 ~ 60 seconds, can the independent programming.

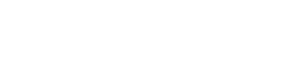

Six, the standard wiring diagram:

Seven, warranty terms:

Users in strict accordance with specifications, under the guidance of correct wiring, installation, maintenance, this product free warranty 1 year.

The following situations to be outside the scope of warranty:

1, to remove the circuit board and various components.

2, lightning or high voltage into the system, circuit board burn out;

More than 3, power supply voltage limit, circuit board burn out

4, power supply box into the water, or other foreign material;

5, correct selection range of the use of the product;

6, sensors or a certain parts of the machine or damaged that touch an injury;

7, not according to specifications correct installation, debugging, and failure to correct maintenance result in product damage or super poor.

Eight, installation steps:

When the drum level gauge has been installed, the air valve, hydraulic valve, drain valve is closed.

Please according to the following steps:

1, slowly open the liquid valve, observe carefully measuring cylinder, weld, flange "run, run, drip, leak" phenomenon.

2, level gauge preheating 2 0 minutes

3, slowly open the valve.

4, check the output 4-2 0 m whether A current signal in the normal range.

5, according to the need to open the drain valve, discharge measurement tube in cold water, sewage, to speed up the circulation and improve measure.

6, after waiting for the normal work of the level gauge, for measuring cylinder do heat preservation processing, this is helpful to improve the accuracy of measurement.

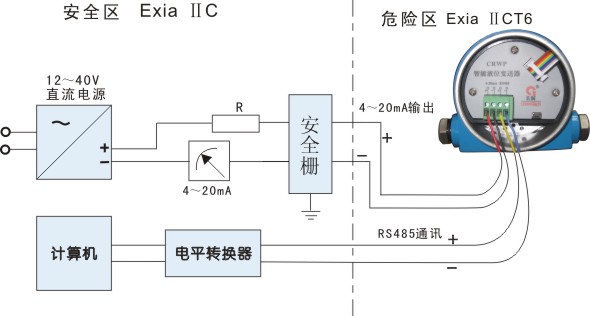

Nine, installation schematic diagram:

Ten, the matters needing attention:

1, the supply of products with product certificate and instruction manual, including product number parameters, wiring diagram, and manufacture date, please check it carefully so as not to use the wrong.

2, when installation should be according to the product connection check site interface is consistent with the product.

3, this product is a precision instrument, banned free disassembly, collision, fall and break.

4, if discovery is unusual, in use should turn off the power to stop using, for inspection or directly to our technical department.5 should be restored the original packaging, transport, store in a cool, dry ventilated warehouse.

6, installation should pay attention to not put sensors in the process of using insulation broken.

7, install the scene to take effective lightning protection measures.

8, this series of any level gauge shell must be reliable grounding, resistance should be less than 4 Ω.

9, using 485 communication network, the level must be equipped with safety barrier and isolator.

10, according to the security gate flame-proof certification, installation should be according to the requirements of the specification.

11, when the transmitter is used to "0" zone to the security of grid power supply power transformer must meet the requirements of article 8.1 GB3836.4-2000.

Eleven, selection of coding:

ZW-BGL | specifications | |||||

mouth | In the special intelligent boiler drum level gauge (wei and control) | |||||

1. pressure≤2.5MPa, the saturated steam temperature | ||||||

mouth | The output signal | |||||

A、4-20mASignal output, LCD display | ||||||

Lmouth | Measuring range | |||||

L1 350mm | ||||||

mouth | Answer the liquid material | |||||

DWhen ordering, please note | ||||||

mouth | The connection method | |||||

MFlange installation,(Nominal diameter) is required to provide | ||||||

Special request, please note | ||||||

Twelve, design selection and ordering information:

1, model specifications: ZW - BGL series;

2, the name of the measured medium, medium density;

3, measurement range, can also be referred to as the nominal length;

4, work pressure, work under pressure;

5, working temperature: measuring the temperature of the liquid;

6, material requirements: liquid material;

7, whether matching supply flange, bolts, nuts, valves, fittings, such as sealing washer;

8, flange standard: nominal size of the flange, 3/4 ", DN25, (, DN80, DN100 or 6;

9, special requirements: before ordering, please indicate in detail.

After-sales service commitment:

Level 1, I companies sell products within twelve months appear quality problem, is responsible for free maintenance.

2, the warranty period, any quality problems such as the products of our company, my company is responsible for free repair or replacement.

3, the warranty period, such as user improper use, damaged products, my company is responsible for the maintenance, charge damage parts cost.

4, after the warranty period appear quality problem, my company is responsible for the maintenance, charge damage parts cost.

5, such as user need to my company site services, to users in the province I company service personnel to reach the site within 12 hours, fujian association of foreign languages and user reach the site within 48 hours.